- Diamond wheels&

CBN wheels - For Surface & Cylindrical

- For Profile grinding

- For Internal grinding

- For Tool grinding

- For Sawing & Cutting

- Diamond &

CBN Electroplated tools - Mounted wheels for internal

- Files and wheels

- Diamond &

CBN Compact tools - PCD tools

- PCBN tools

- Wear resistant parts

- Natural Dia. Cut. tools

- Diamond dressers

- Diamond hand-stones

- Other products

- Inquire

- Click Here

- Call us

- +81-3-3759-7405

HOME > Diamond &CBN Compact Cutting tools > Diamond Compact Cutting tools

Diamond Compact Cutting tools

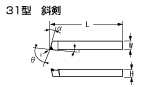

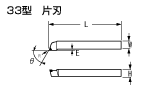

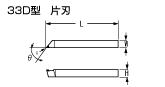

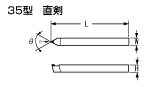

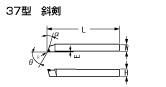

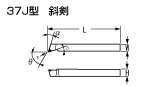

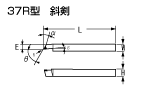

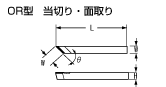

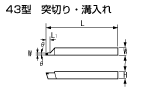

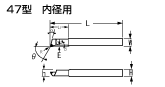

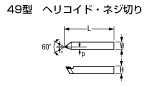

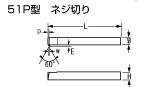

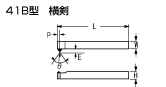

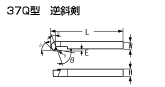

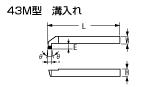

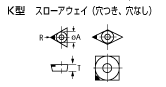

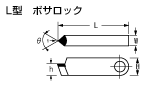

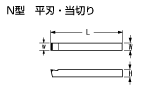

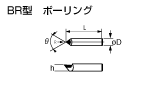

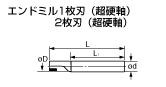

Shapes

Cobalt base alloy: Stellite, Colmoroy, warrex

Diamond Compact tools

Diamond Compact tools have superior wear resistance to any other tool materials. Diamond compact is made of tungsten carbide substrate and the polycrystalline diamond composits, sintered together into one piece. Therefore, it has impact resistance and rigidity of tungsten carbide and no cleavage plane of polycrystalline diamond, all of which protects the diamond compact tool from chipping and cracking hence gives a longer tool life while it shows excellent performance. Furthermore, it also shows remarkable works on truing and dressing of alumina and silicon carbide wheels.

Features of Diamond Compact Tools

- Workpieces which generate quick wear on tungsten carbid turning tools or ceramic turning tools are suited.

- Hardness and wear resistance are always consistent in any direction that makes the tool to improve efficiency in machining and stable in operation for long hours.

- Diamond compact has better impact resistance than that of natural diamond.

- It doesn't generate built-up edge easily so fine finished surface can be achieved consistently.

- It shows very good performance in heavy grinding and combination grinding.

- It has sharp cutting ability with which high precise surface can be made.

However, it can apply to finishing at level of 0.25~0.4μmRam but not mirror finish. - It cannot applu to ferrous material machining.

- It can be used again after the cutting edges are re-ground.

Cutting condition of Diamond Compact tools

| Workpieces | Cutting speed(m/min) | Depth of cut(mm) | Feed(mm/rev) |

|---|---|---|---|

| Aluminium | 460 ~ 1500 | 0.5 ~5.0 | 0.05 ~ 0.2 |

| Bronze | 330 ~ 1000 | 0.1 ~0.5 | 0.02 ~ 0.15 |

| Tungsten carbide | 120 ~ 450 | 0.01~0.15 | 0.02 ~ 0.08 |

| G F R P | 120 ~ 1100 | 0.1 ~1.0 | 0.02 ~ 0.25 |

| C F R P | 150 ~ 600 | 0.1 ~1.0 | 0.1 ~ 0.4 |

| Aluminum Ceramics | 120 ~ 450 | 0.01~0.15 | 0.02 ~ 0.1 |