- Diamond wheels&

CBN wheels - For Surface & Cylindrical

- For Profile grinding

- For Internal grinding

- For Tool grinding

- For Sawing & Cutting

- Diamond &

CBN Electroplated tools - Mounted wheels for internal

- Files and wheels

- Diamond &

CBN Compact tools - PCD tools

- PCBN tools

- Wear resistant parts

- Natural Dia. Cut. tools

- Diamond dressers

- Diamond hand-stones

- Other products

- Inquire

- Click Here

- Call us

- +81-3-3759-7405

HOME > Diamond &CBN Compact Cutting tools > CBN Compact Cutting tools

CBN Compact Cutting tools

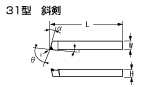

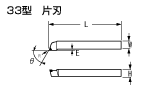

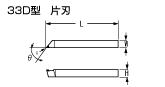

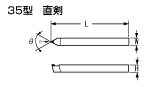

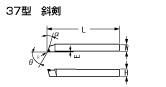

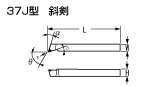

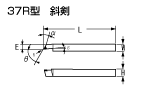

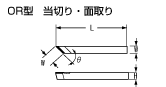

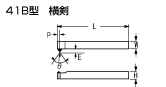

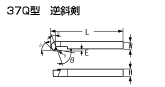

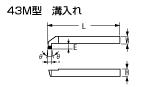

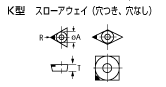

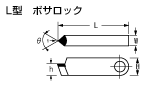

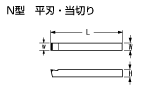

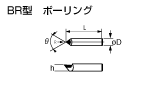

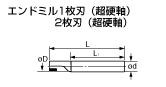

Shapes

CBN Compact tools

CBN Compact tools are made of tungsten carbide substrate and the polycrystalline CBN composits sintered together into one piece. It shows remarkable performance in grinding as well as in profiling the complicated shape.

Features of CBN Compact tools

- HRIt is most suited for grinding ferrous materials of above C50.

- HRFerrous materials below C45 can be machined but in respect of economy it is not recommended.

- High rate of material removal can be achieved hence improvement in grinding efficiency

- High speed grinding can be carried out so it saves product cost.

- When working temperature becomes high, chemical reaction isn't occurred so easily, so cutting edges cannot be blunt at short time.

- High quality surface at high precision level can be achieve so it improves accuracy of machined workpiece.

- If you use coolant, the tool life will be much improved.

- The tool can be used after re-ground

Cutting condition of CBN Compact tools

A cutting condition example of CBN Compact tools

| Workpiece | Cutting speed (m/min) |

Depth of cut (mm) |

Feed (mm/rev) |

|---|---|---|---|

| aluminium | 460-1500 | 0.5-5.0 | 0.05-0.2 |

| bronze | 330-1000 | 0.1-0.5 | 0.02-0.15 |

| Super Hard Alloy | 120-450 | 0.01-0.15 | 0.02-0.08 |

| GFRP | 120-1100 | 0.1-1.0 | 0.02-0.25 |

| CFRP | 150-600 | 0.1-1.0 | 0.1-0.4 |

| AlumiSeramics | 120-450 | 0.01-0.15 | 0.02-0.1 |

A cutting condition example of CBN Compact tools(rough)

Workpiece |

Cutting speed (m/min) |

Depth of cut (mm) |

Feed (mm/rev) |

Workpiece |

Cutting speed (m/min) |

Depth of cut (mm) |

Feed (mm/rev) |

|---|---|---|---|---|---|---|---|

SKD 12 |

76 |

1.5 |

0.12 |

Incolloy 901 |

240 |

3.2 |

0.15 |

SKD 11 |

80 |

1.5 |

0.25 |

Inconel 600 |

183 |

3.2 |

0.15 |

SNCM 21 |

76 |

1.5 |

0.2 |

Colmonoy |

183 |

3.2 |

0.08 |

Chilled cast iron |

121 |

5.0 |

0.2 |

K - Moneru |

183 |

3.2 |

0.15 |

Meehanite cast iron |

183 |

6.3 |

0.2 |

Rune 41 |

183 |

3.2 |

0.15 |

SKH 9 |

76 |

1.5 |

0.2 |

Rune 95 Forging |

137 |

3.2 |

0.12 |

Moricrome |

91 |

3.2 |

0.2 |

Stellite |

183 |

3.2 |

0.15 |

SUJ 2 |

76 |

1.2 |

0.38 |

Waspaloy |

183 |

1.5 |

0.08 |